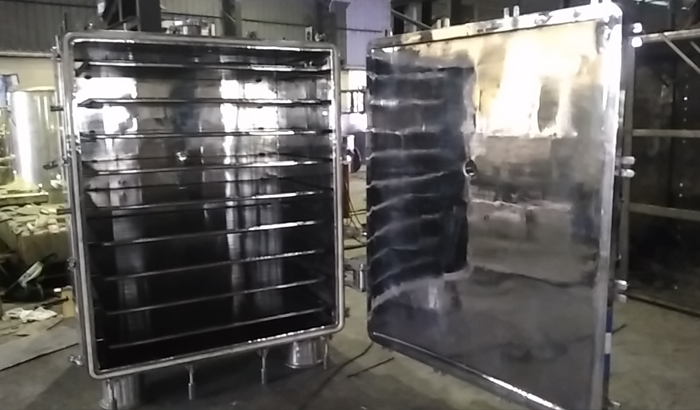

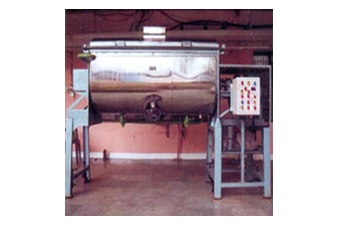

Air Tray Dryer

An Air Tray Dryer Is used for the best drying results in conventional process. It consists of a double-walled cabinet with one or two doors. The gap between two walls is filled with light resin-bounded fibreglass wool insulation material to avoid heat loss. The doors are provided with gaskets to avoid air leakages from the front side of the door. Stainless steel trays are placed inside the chamber. cGMP model dryers are designed to dry specific products.